|| Product Introduction

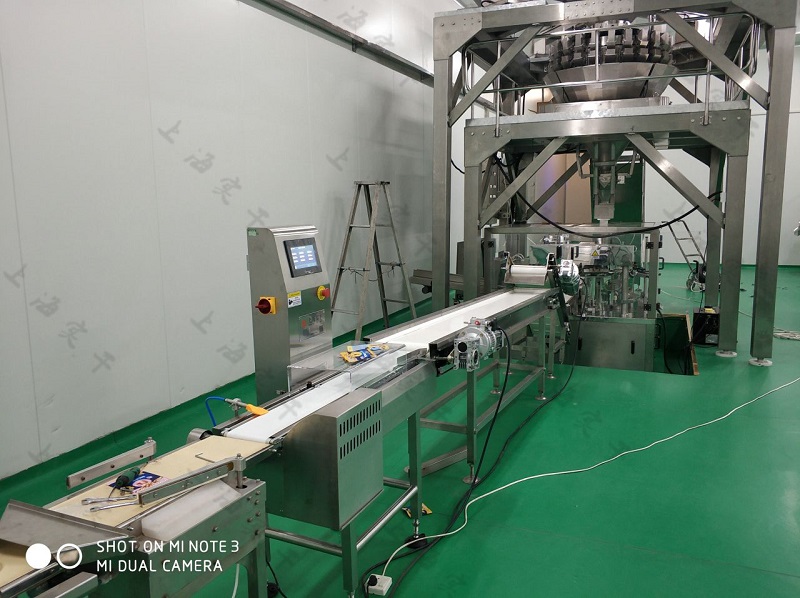

2g-1kg Capsule/Tablet Cartons Online Checkweigher Systems are used for 100% automated weight verification of pharmaceutical boxes (primary/secondary packaging) in production/packaging lines, ensuring:

Compliance with regulatory weight tolerances.

Detection of missing components (leaflets, capsule,tablet).

Prevention of under/overfilled boxes from reaching distribution.

Checkweigher for Pharma

|| Tech Specifications

Type:SG-220U

Weighing Range:5-1500g

Limited of product:L: 300 W:220 H: 3-200mm

Accuracy:±0.2g Depends on product

Division Scale:0.1g

Belt Speed:0- 60m/min

Max Speed:100 pcs/min

Belt Width:220mm

Machine Weight:65kg

Power Supply:AC 220V 50HZ

Power:200W

Main Material:SUS304 stainless steel

|| Main Features

1.Infeed Conveyor:Gently aligns boxes entering the system at line speed (e.g., 100+ boxes/min).

2.Weighing Bridge:High-precision load cell(s) measures box weight (±0.1–0.5% accuracy).

3.Rejection Mechanism:Removes non-conforming boxes (pneumatic pusher avoiding product contact).

4.HMI Control Panel:Touchscreen interface for operators (password-protected, audit trail).

5.Outfeed Conveyor:Transports accepted boxes to downstream processes (labeling, aggregation).

|| Application

|| Our Customers

|| Our Exhibitions

|| Package & Shipping

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

TAGS:

Capsule Checkweigher

Multi-Lane Check Weigher

Pharmaceutical Checkweigher

Capsule Tablet Metal Detector