|| Product Introduction

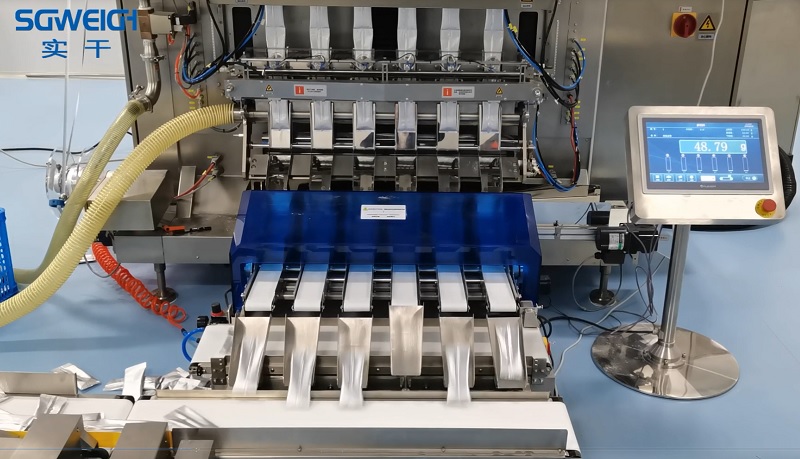

The 4-5 lane Liquid Juice Sticks Checkweigher is an online inspection device specifically designed for downstream multi-row packaging machines.Multi line Check Weight Machine can simultaneously and independently weigh multiple parallel strips of packages, and accurately identify and reject individual products with substandard filling (empty packages, underfilled packages, overfilled packages) without affecting the overall line speed.

|| Tech Specifications

Model:SG-4-6X

Weighing range:1-50g

Accuracy:0.01g (Depends on products)

Weighing speed:The single-lane speed can reach up to 70 pcs/min (depending on the length of the product)

Restrictions of product:L:180 W:40 H:2-20(mm)

Operation way:Touch screen

Operation screen:12 inch screen

Material:Stainless steel(SUS304)

Power supply:220V 50-60HZ

Power:About 200W

Remark:The properties of the tested products and the use environment are different, and the detection speed and accuracy are also different. The actual test is the standard.

|| Main Features

1. High-Speed Synchronous Independent Detection

The equipment can simultaneously weigh 4-5 parallel rows of bags. Each row is equipped with an independent sensor, ensuring accurate measurement of the true weight of each bag of juice, even with extremely narrow spacing, without interference.

2. Precise Identification and Single-Row Rejection

Based on a preset weight range, the system identifies empty bags, underfilled bags, or overfilled defective products in real time. Combined with a flip-plate mechanism, it rejects only defective products from that row, without affecting the operation of other normal rows, greatly reducing the false rejection rate.

3. Data Reporting

The system continuously records data, providing real-time and historical reports on production quantity, rejection quantity, average weight, and statistical process control data.

4. Strict Hygiene and Waterproofing

The equipment features an all-stainless steel and waterproof design. The conveyor belt can be quickly disassembled and cleaned to prevent bacterial growth, fully meeting food safety requirements.

|| Application

|| Our Customers

|| Our Exhibitions

|| Packaging & Delivery

● Our machines undergo comprehensive testing and commissioning before shipment to ensure stable and reliable performance.

● Equipment is packaged in thickened wooden crates with shock and moisture-proof interiors to effectively prevent damage during transportation.

● We partner with several professional international logistics companies and support a variety of shipping methods, including sea, air, and land transport.

● Ensure the equipment arrives safely and on time at your facility.

TAGS