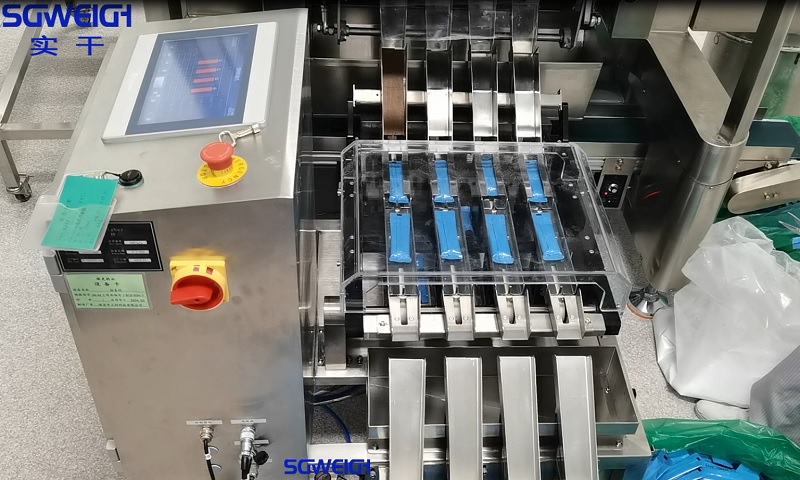

With the increasing speed of production lines and demand for multi-lane packaging in the food, pharmaceutical, and daily chemical industries, traditional single-lane checkweighing methods are no longer able to meet the efficiency requirements of modern production. To address this, our company has launched the next-generation 4-Lane Checkweigher, which utilizes multi-lane parallel weighing technology to provide users with a more efficient and accurate weight verification solution.

The 4-Lane Checkweigher utilizes a multi-lane synchronous detection structure, enabling simultaneous high-speed weighing of products on four production lines, significantly improving overall inspection capabilities. The device’s built-in high-precision dynamic weighing system and intelligent data processing algorithms ensure accurate and stable results for each lane, effectively eliminating substandard products and ensuring consistent product quality.

◆The compact design and small footprint allow for flexible integration into multi-lane packaging machines and automatic cartoning lines.

◆The touchscreen interface supports multi-language display and features data statistics, history logging, and alarm traceability, facilitating quality analysis and production management.

◆The equipment is constructed of food-grade stainless steel, complies with GMP and HACCP standards, and is easy to clean and maintain.

This Four-row Checkweigher not only significantly improves inspection efficiency on multi-row production lines but also helps companies achieve automated and intelligent production management, providing strong support for improving product quality and production competitiveness.

TAGS