|| Product Introduction

The Bagged Product Metal Detector is a high-precision, in-line inspection device designed specifically for finished bagged food, daily chemicals, pharmaceuticals, and chemical products. Using a highly sensitive electromagnetic induction system, the device effectively detects foreign metals such as iron (Fe), non-ferrous metals (such as copper and aluminum), and stainless steel (SUS) in the product, ensuring product safety and quality.

|| Tech Specifications

Type:SG-M400

Detection sensitivity: in empty state

H-100mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ1.5mm

H-120mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-150mm: Fe≥Φ1.0mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-200mm: Fe≥Φ1.2mm, Non-Fe≥Φ2.0mm, SUS≥Φ2.5mm

Effective detection hole width: 150-1000mm customized according to requirements

Effective detection hole height: 80-500mm customized according to requirements

Maximum speed of conveyor belt: 25m/min

Conveyor belt material: food grade PU belt

Protection class: IP65

Display and operation mode: LED fast key input

Machine weight: about 120kg

Power requirements: AC220V 50HZ

Power: 200W

Alarm mode: metal detection, alarm belt stop or automatic removal

|| Main Features

1. High-Sensitivity Detection Performance

Advanced multi-frequency or dual-frequency detection technology automatically identifies product characteristics, effectively suppressing the “product effect” and maintaining stable detection sensitivity even for highly conductive materials such as those containing water and salt.

2. Intelligent Operating System

Equipped with a 7-inch touchscreen or push-button interface, with a choice of Chinese and English menus, it offers intuitive operation. An auto-learning function quickly memorizes different product parameters, enabling rapid switching between multiple varieties.

3. Diverse Rejection Systems

Depending on the weight and packaging type of the bagged product, a selection of air-blowing, lever-type, flap-type, or belt-type stop alarm-type reject mechanisms are available to ensure accurate separation of defective products.

4. Structure and Protection

The all-304 stainless steel body meets food hygiene requirements. The detection head has an IP65/IP66 protection rating, making it suitable for production environments with high humidity or frequent cleaning.

5. Data Logging and Traceability

The system features detection logging and statistical functions, and supports USB data export.

6. Compliant with Multiple Standards

This product complies with international food safety management system requirements, including HACCP, and can be seamlessly integrated with automated packaging lines, checkweighers, and conveyor systems.

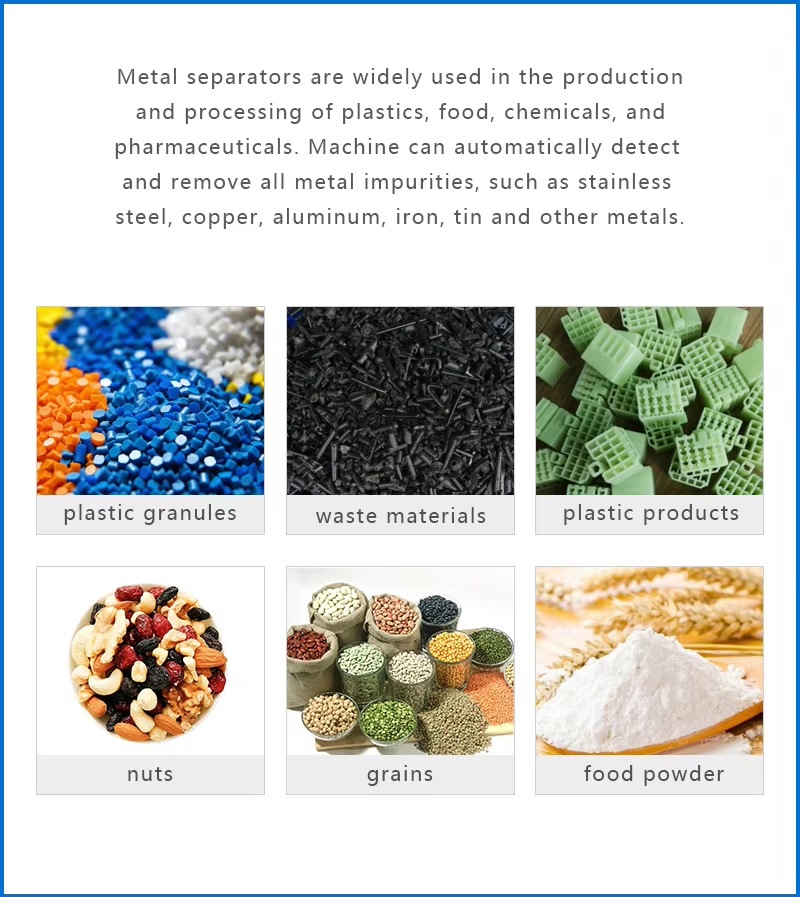

|| Application

Production lines for packaged foods such as snack foods, seasonings, dried fruits and nuts, frozen foods, candies and biscuits;

Inspection of industrial bagged products such as laundry detergent, fertilizer, and chemical powders;

Foreign matter detection in small-packaged products such as pharmaceuticals and health supplements.

|| Our Customers

|| Our Exhibitions

|| Packaging & Delivery

Our machines is fully tested and calibrated before delivery.

It is packed in a strong wooden case with internal shockproof protection.

Various shipping options are available — by sea, air, or land — ensuring safe and on-time delivery by professional logistics partners.

TAGS