|| Product Introduction

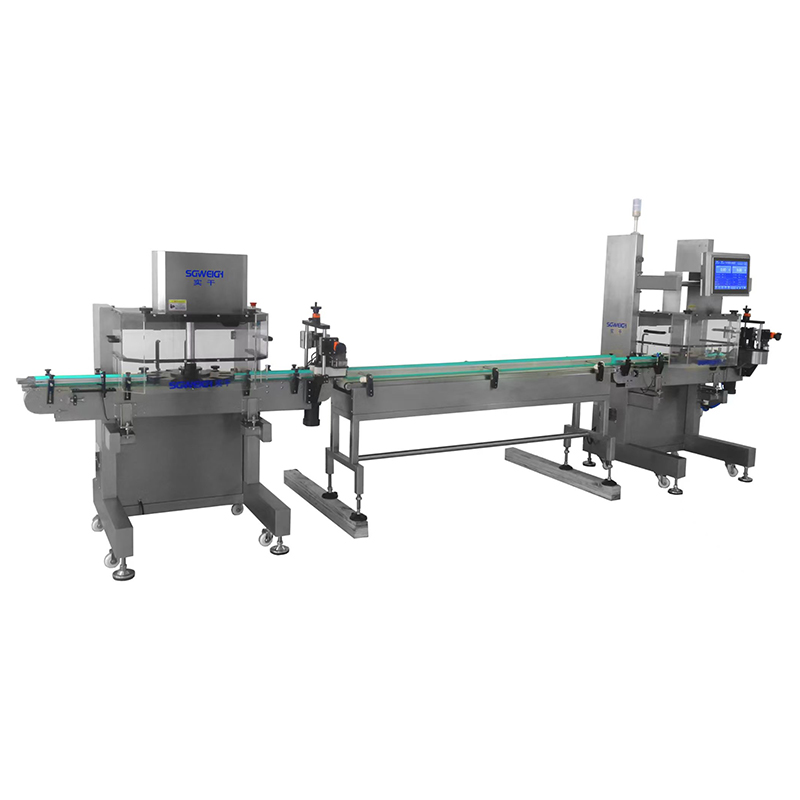

The Multi-Line Large Checkweigher is an online weight detection device specifically designed for high-speed, multi-row production lines. It is suitable for packaging and dispensing processes requiring high capacity, high precision, and continuous automation.

This Multi lane Sticks Online Checkweighing System employs a multi-row independent weighing structure, with each row equipped with a high-sensitivity weighing sensor and independent algorithm, ensuring stable and reliable detection accuracy even at high speeds.

In terms of structural design, the equipment supports linear or modular layouts, facilitating connection to multi-row conveyor lines, material discharge channels, or packaging machine exits. The robust frame is suitable for long-term continuous operation, meeting the high-load, high-cycle application requirements of the food, pharmaceutical, daily chemical, and industrial product industries.

|| Tech Specifications

Model:SG-6X (Customizable)

Weighing Range:1-200g

Accuracy: 0.1 gram (depending on the product)

Speed:40-60pcs/min (one lane)

Conveying Speed:20-100m/min

Operation Method:Touch operation

Elimination Method:Lifting Rejection

Belt Height From The Ground:Can be customized according to customer requirements

Machine Structure:Stainless steel (SUS304)

Power Supply:220V 50-60HZ

Power:About400W

Windshield:Thick acrylic (to avoid airflow interference)

|| Main Features

1. 6-Column Synchronous Online Dynamic Checkweighing: Simultaneous weighing of multiple columns of products, adaptable to high-speed multi-column production lines, significantly improving overall capacity.

2. High-Precision Weight Detection: Employs high-sensitivity weighing sensors and dynamic filtering algorithms to ensure stable and reliable weighing results.

3. Automatic Overweight/Underweight Detection: Automatically identifies unqualified products by comparing with set weight ranges in real time.

4. Independent Column Rejection System: Each column can be independently controlled for rejection, avoiding accidental rejection and cross-interference.

5. Seamless Integration with Production Lines: Supports integration with filling machines, packaging machines, counting machines, and multi-column conveyor systems.

6. Real-Time Weight Data Acquisition: Automatically records weighing data for quality statistics and process monitoring.

7. Product Formula Management: Stores multiple sets of product parameters, allowing for quick switching between different specifications.

8. Alarms and Status Indicators: Automatic alarms for exceeding limits, continuous non-conformities, and equipment malfunctions.

9. Human-Machine Interface Operation: Touchscreen operation; intuitive parameter settings and clear operational status.

10. Communication and System Integration Supports communication methods such as PLC / Ethernet / RS485, facilitating integration with MES / ERP systems.

|| Application

|| Our Customers

|| Our Exhibitions

|| Packaging & Delivery

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

TAGS