|| Product Introduction

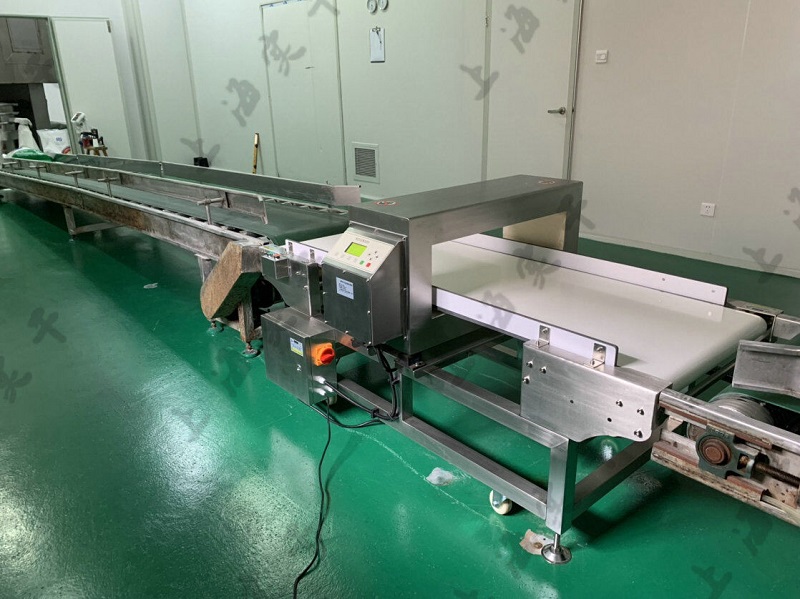

Candy Chocolate Food Grade Conveyor Metal Detector is an essential quality control device used in the food processing and packaging industry to detect and reject metal contaminants in products moving along a conveyor belt. These contaminants could include ferrous, non-ferrous, and stainless steel particles that may have entered the product during processing.

Customized High Precision Metal Detector

|| Tech Specifications

Name:Metal Detector

Detection sensitivity: in empty state

H-100mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ1.5mm

H-120mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-150mm: Fe≥Φ1.0mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-200mm: Fe≥Φ1.2mm, Non-Fe≥Φ2.0mm, SUS≥Φ2.5mm

Effective detection hole width: 150-1000mm customized according to requirements

Effective detection hole height: 80-500mm customized according to requirements

Maximum speed of conveyor belt: 25m/min

Conveyor belt material: food grade PU belt

Protection class: IP65

Display and operation mode: LED fast key input

Machine weight: about 120kg

Power requirements: AC220V 50HZ

Power: 200W

Alarm mode: metal detection, alarm belt stop or automatic removal

1. The above detection accuracy is for reference only. The actual detection accuracy will be obtained after testing.

2. Special specifications can be customized according to customer requirements.

3. The material used for the metal detection device is SUS304, dustproof and waterproof.

4. The sense of detection is related to the properties of the tested product (humidity, temperature, salt content, mineral matter, etc.).

|| Main Features

1. Can be used almost anywhere in food processing lines to ensure the safety of processing and packaging lines.

2. Operate at various speeds to adapt to various food production lines.

3. Check product types: bulk/boxed/bagged/bottled, etc.

4. Suitable for food, aquatic products, frozen meat and daily necessities, etc.

5. 304SUS bracket, easy to clean and maintain.

6. Very simple to operate.

|| Application

Food, pharmaceutical, chemical, rubber, ice, ice products, toys, shoes, leather, knitting, printing and other industries to detect the metal impurities in the production process or raw materials, such as: iron, non-magnetic metal Items (silver, steel, aluminum, stainless steel and other non-ferrous metals can be detected), improve product safety factor and reduce hazards.

|| Our Customers

|| Our Exhibitions

| CPHI China Exhibition(2025) | ProPak China Exhibition(2025) |

|| Package & Shipping

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

FAQ

Q1. Are you a manufacturer or trader?

A: We are a manufacturer and we are located in Shanghai,China. We have our own design team for product design.

Q2: Can you explain the whole transaction process?

- Understand the specific needs of customers and determine the machine details.

- Sign the contract.

- Pay the deposit.

- The factory arranges production.

- Test and inspect the machine before shipment.

- Check by customers through online or on-site testing.

- Shipment and transportation, balance payment.

Q3.How much does Conveyor Metal Detector cost?

There is no quick, easy answer to this question.Our machine is specific to the customer, so arriving at ‘standard pricing’ isn’t usually practical. Pricing largely depends upon your unique needs, such as the products you want to detect, the size of the product,the speed you want to achieve,or the complexity of the process. Contact us to get a specific quote.

Q4. What kind of shipping method can you provide?

A: By sea, by air and by international express.We will send the photo and video of machine to customer to check the machine running situation before delivery.

Q5. Do you accept customer logo and customization?

A: We accept all kinds of customization and logo for our customers for all our products.

Q6. How about the packing for product? Is it easy damaged during transportation?

A: No.We takes of wooden case and it is very safe.

TAGS:

Capsule Checkweigher

Multi-Lane Check Weigher

Pharmaceutical Checkweigher

Capsule Tablet Metal Detector