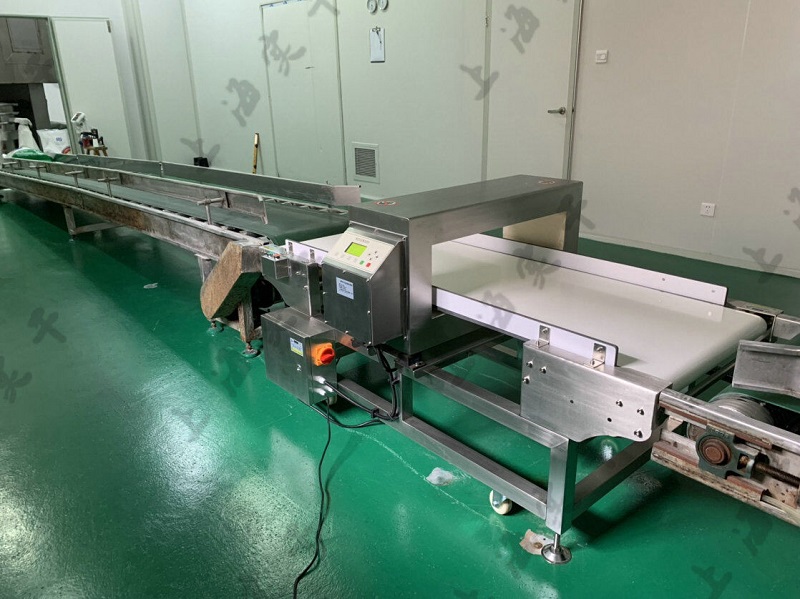

■ Product Introduction

Conveyor Metal Detectors are key equipment in the food processing industry, which can detect and remove metals such as iron and stainless steel from the process or packaged items.Metal Detector for Food Processing Line is essential to ensure food safety and prevent potentially harmful metal fragments from falling into the hands of consumers.

Food Safety Conveyor Metal Detector

■ Tech Specifications

Type:SG-M400 (Customize)

Machine Grade:Food Grade

Detect method:Electromagnetic wave detection

Detecting width:150-1000mm customized according to requirements

Detecting height:80-500mm (or custom-made)

Detecting sensitivity:Fe 0.3mm, Non-Fe 0.5mm, SUS 0.5mm

Detecting adjustment:Intelligent adjustable

Belt Speed:25m /min (or specified)

Alarm mode:The buzzer alarm, the motor automatically stop

Power:AC220V,50/60Hz (Or Customized)

■ Main Features

1. Excellent stability and high sensitivity.

2. Suitable for all metals, including ferrous metals, copper, stainless steel, etc.

3. Dustproof and waterproof stainless steel structure.

4. Can be equipped with a variety of rejector styles (push rod, flap, jet, etc.).

5. Can be used almost anywhere in the food processing line.

6. For detecting magnetic and non-magnetic metals.

7. Protect your brand and maintain your reputation.

■ Application

■ Customers

■ Exhibitions

■ Package & Shipping

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

TAGS:

Capsule Checkweigher

Multi-Lane Check Weigher

Pharmaceutical Checkweigher

Capsule Tablet Metal Detector