Product Introduction

Heavy Weight Industrial Checkweigher is typically designed to handle larger, heavier products or packages.Box Inline Check Weigher Machines are built to weigh items in high-speed production environments, ensuring that they meet the specified weight tolerance.

Tech Specifications

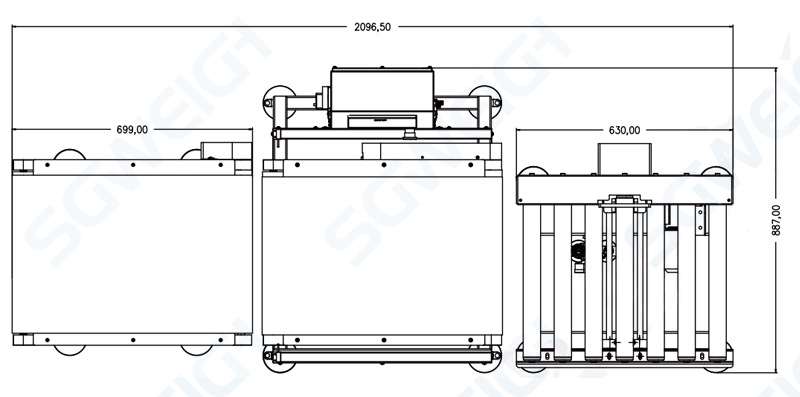

Type:SG-450

Weighing Range:0.05-20/30kg

Limited of product:L: 550 W:450 H: 3-400mm

Accuracy:±5/10g Depend on products

Division Scale:0.1g

Belt Speed:0-60 m/min

Max Speed:40 pcs/min

Belt Width:450mm

Machine Weight:40+70+45kg

Power Supply:AC 110/220V ±10% 50HZ

Power:400W

Main Material:SU304 stainless steel

Main Features

1.7 inch touch screen, easy and friendly operation.

2.Real-time weighing curve, real-time statistical analysis.

3.Modular structure, easy to disassemble and assemble, easy to maintain, stable and reliable.

4.Reject unqualified products accurately, eliminate waste of raw materials, and ensure product quality.

5.Real-time logging, data can be exported for analysis.

Application

Our Company

Our Customers

Our Exhibitions

Package & Shipping

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.