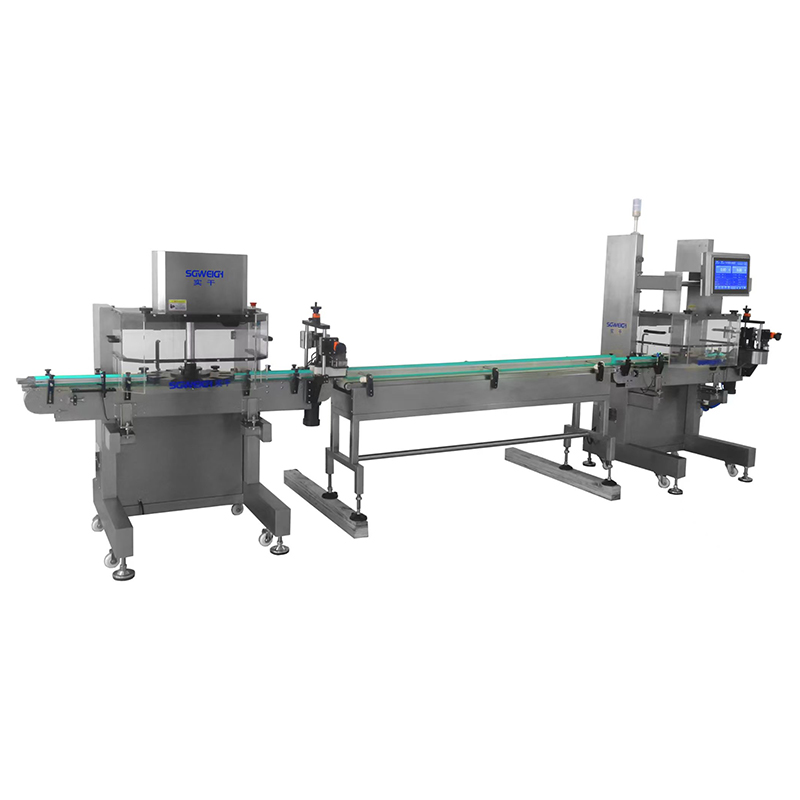

■ Product Overview

The Bottles Rotary Checkweigher is a high-precision online weighing device specifically designed for bottled products, widely used in automated production lines in industries such as pharmaceuticals, food, beverages, and daily chemicals. This Bottles Conveyor Checkweigher employs a rotating star wheel-type bottle-separating structure, ensuring each bottle maintains a stable posture during the weighing process, effectively avoiding weighing errors caused by bottle swaying in traditional linear conveyor weighing.

■ Tech Specifications

Model: SG-Z2 (dual channel)

Weighing range: 5-300g

Minimum scale: 0.01g

Sorting accuracy: ±0.02 grams (depending on the product)

Sorting speed: maximum 50 pieces/minute (single channel)

Conveying speed:0-50m/min

Operation mode: touch operation

Conveying direction: Facing the touch screen from left to right

Rejection method: air blowing removal/push plate removal

Machine structure: stainless steel (SUS304)

Power supply: 220V 50-60HZ

Power: about 1500W

■ Main Features

1. Large color LCD touch screen interface, easy to operate and intuitive to display.

2. Chinese and English user interface.

3. Equipped with automatic photoelectric detection of empty packages, and the conveyor belt speed is adjustable.

4. Parameter settings are protected by three-level passwords and can only be operated by managers.

5. Product weighing data can be exported via USB.

6. Power-off protection function, unexpected power-off parameters remain unchanged.

7. The parameters of different products can be set to store 100 kinds of detection data, making it convenient for users to switch and call.

8. Data statistics function. The total number of products passed within a period of time/the total number of underweight products/the total number of overweight products.

9. The mechanical structure is simple and the buckle-type conveyor belt is easy to disassemble, clean and maintain.

10. Automatic dynamic compensation value and dynamic zero-point tracking, including zero-point tracking during continuous operation of the equipment, ensure reliable detection data.

11. The curve graph/bar graph displays the statistical distribution of the sorting (re-inspection) results.

■ Application

■ Customers

■ Exhibitions

■ Packaging & Delivery

● Our machines undergo comprehensive testing and commissioning before shipment to ensure stable and reliable performance.

● Equipment is packaged in thickened wooden crates with shock and moisture-proof interiors to effectively prevent damage during transportation.

● We partner with several professional international logistics companies and support a variety of shipping methods, including sea, air, and land transport.

● Ensure the equipment arrives safely and on time at your facility.

TAGS

High Speed Small Bottle Containers Rotary Checkweighe

CE Checkweigher Pouches Conveyor Weight Checker

Online Inclined Conveyor Checkweigher

4 Lane Stick Weight Checker 3 in 1 Coffee Online Checkweigher

Pharma Nutraceutical Metal Detector for Tablet Capsule

Automatic Conveyor Metal Detector for Pouch Packaging