■ Product Introduction

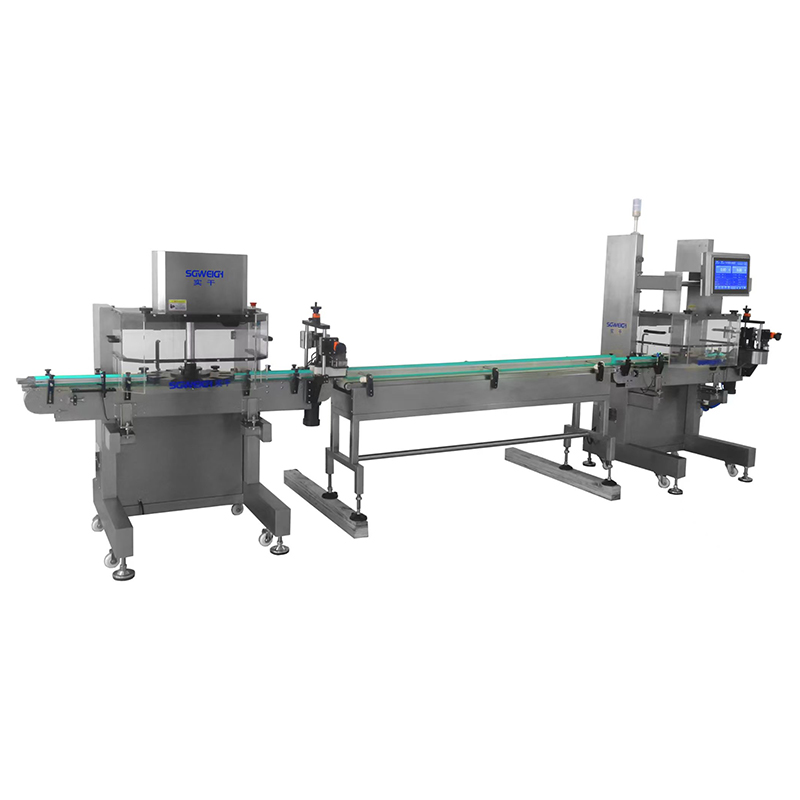

In-line Dynamic Cosmetic Tubes Checkweigher is a specialized weighing machine designed to ensure that cosmetic tubes (e.g., lotion, cream, gel, or serum tubes) meet precise weight specifications before packaging.Industrial Weight Checker helps maintain quality control, reduces giveaway (overfilling), and prevents underfilled products from reaching consumers.

■ Tech Specifications

Model:SG-150

Weighing range:5-500g

Minimum scale:0.1g

Checking speed :Max 120pcs/Min

Belt speed:0-65m/min

Box size limit:Length:200mm Width:150mm Height:3-200mm

Operation Way:Touch operation

Conveying direction:Facing the touch screen from left to right

Rejection method:Push Rejection

Belt height from the ground:750±50mm(can be customized)

Machine material:Stainless steel(SUS304)

Power supply:220V50/60HZ

Power:About300W

■ Main Features

1.High-Precision Weighing

Measures filled tubes with high accuracy (typically ±0.1g to ±0.5g, depending on product requirements).

Suitable for various tube sizes.

2.Automatic Rejection System

Removes underweight or overweight tubes from the production line (using air blasts, pushers, or diverter arms).

3.User-Friendly Interface

Touchscreen HMI for easy setup, calibration, and data logging.

4.Integration with Filling & Packaging Lines

Works seamlessly with tube fillers,cappers, and labeling machines.

Can be placed inline after filling or before final packaging.

■ Application

■ Company

■ Customers

■ Exhibitions

■ Package & Shipping

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

TAGS:

Capsule Checkweigher

Multi-Lane Check Weigher

Pharmaceutical Checkweigher

Capsule Tablet Metal Detector