Product Overview

Pipeline Metal Detector for Sauce and Liquid is specifically designed to detect and reject metal contaminants from sauces, pastes, and liquid food products during production.The Metal Detection Systems ensures effective detection and removal of all types of metal contaminants, guaranteeing product safety and quality.

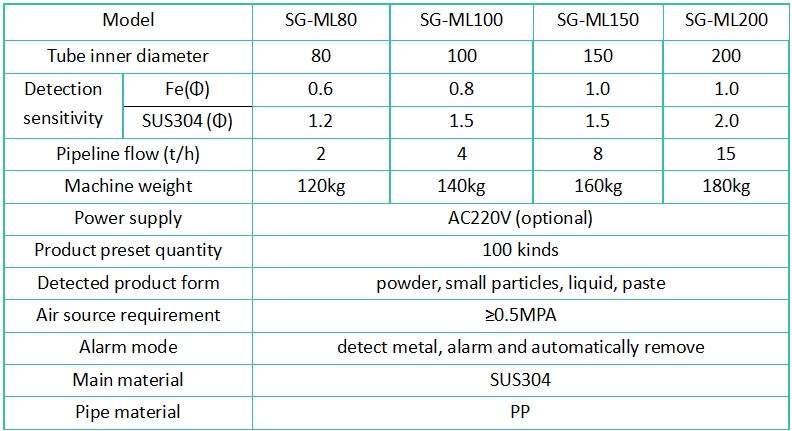

Product Parameter

Model: SG-ML80/SG-ML100/SG-ML150/SG-ML200

Tube inner diameter: 80/100/150/200

Detection sensitivity: Fe (Φ)-0.6/0.8/1.0/1.0

SUS304 (Φ): 1.2/1.5/1.5/2.0

Pipeline flow (t/h): 2/4/8/15

Machine weight: 120kg/140kg/160kg/180kg

Power supply: AC220V (optional)

Product preset quantity: 100 kinds

Detected product form: powder, small particles, liquid, paste

Air source requirement: ≥0.5MPA

Alarm mode: detect metal, alarm and automatically remove

Main material: SUS304

Pipe material: PP

Standard Features

Sensitivity Settings:

Pipeline metal detectors allow users to adjust the sensitivity level based on the size and type of metal contaminants they need to detect. This feature ensures optimal detection and minimizes false alarms.

Automatic Rejection System:

When metal contaminants are detected, pipeline metal detectors can trigger an automatic reject system to divert the contaminated material from the mainstream. This helps maintain product integrity and prevent further contamination downstream.

Rugged Construction:

Pipeline metal detectors are designed to meet the demands of industrial environments. They are typically made of durable materials such as stainless steel to resist corrosion and ensure longevity.

Easy Integration:

Designed to be easily integrated into existing piping systems. They typically have flange connections or other fittings that allow for seamless installation without interrupting the flow of materials.

User-Friendly Interface:

Equipped with a user-friendly interface, typically with a touchscreen display or control panel. These interfaces allow operators to adjust settings, monitor performance, and receive real-time feedback.

Scope of Application

Sauces:

Detects metal contaminants in a variety of sauces such as ketchup, mayonnaise, hot sauce, BBQ sauce, salad dressing, and pasta sauces.

Soups and Broths:

Ensures that soups, broths, and ready-to-serve liquid meals are free from metal particles during production and packaging.

Condiments:

Effective in detecting metals in condiments like mustard, soy sauce, vinaigrettes, and other liquid condiments used in the food industry.

Paste and Purees:

Detects metal contaminants in paste-like products, such as tomato paste, fruit purees, and other thick or semi-thick pastes used in food processing.

Dips and Spreads:

Used to detect metals in products like hummus, salsa, guacamole, and other spreadable products during manufacturing.

Beverages:

Detects metal contaminants in liquid beverages such as fruit juices, energy drinks, soft drinks, and dairy beverages during the bottling and packaging process.

Company Profile

Customer Visit

Exhibition

Packaging&Shipping

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.