■ Product Overview

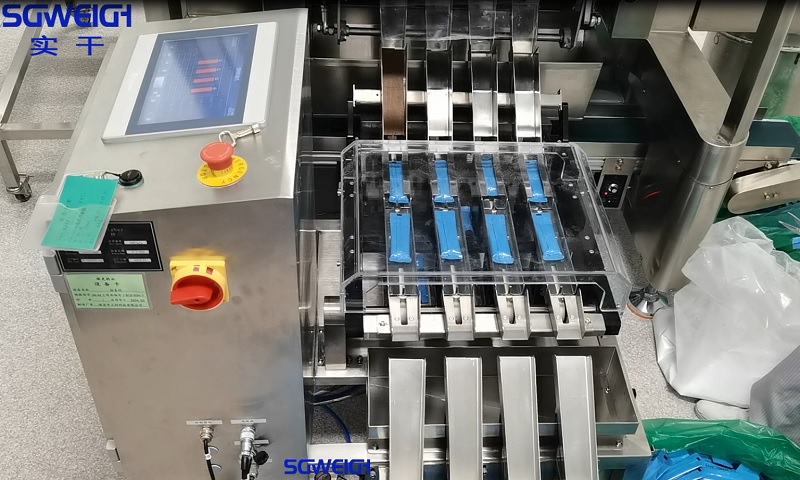

The Four-lane Checkweigher is a high-speed online weighing device developed for multi-channel, high-efficiency packaging production lines. It can simultaneously perform real-time weight detection on products in four conveyor channels, achieving a high-capacity, high-precision, and low-footprint checkweighing solution.Dynamic 4 Lane Checkweighe is widely used in food, pharmaceutical, daily chemical, and small-package solid goods production scenarios, and is especially suitable for high-speed automated packaging lines for small bags, stick-shaped foods, and small sample bags.

■ Tech Specifications

Model:SG-4X

Weighing range:1-50g

Accuracy:0.01g (Depends on products)

Weighing speed:The single-lane speed can reach up to 70 pcs/min (depending on the length of the product)

Restrictions of product:L:180 W:40 H:2-20(mm)

Operation way:Touch screen

Operation screen:12 inch screen

Material:Stainless steel(SUS304)

Power supply:220V 50-60HZ

Power:About 200W

■ Main Features

1. Four-lane Synchronous Dynamic Weighing Function:

■The equipment is equipped with four independent weighing units, enabling synchronous, real-time dynamic weighing of products from four production channels.

■Each channel processes data independently.

■No interference, high stability.

■Significantly increases overall production line capacity.

2. Automatic Weight Sorting Function:

Based on the set weight range (upper limit, lower limit, acceptable range), the system automatically determines the weight status of each product:

■Automatic release of qualified products

■Automatic rejection of overweight/underweight products.

3. Multi-lane Independent Rejection Function:

■Each channel can be equipped with an independent rejection system.

■Ensuring accurate rejection of products with different weight abnormalities without affecting the operation of other channels.

4. High-Speed Data Processing and Statistical Function:

The system can display and record production data from all four channels in real time:

■Pass rate, NG quantity statistics.

■Average weight, trend chart.

■Batch production report export.

■USB/LAN network data upload.

■Achieve intelligent quality management.

5. Product Formula Management Function:

■Features a touchscreen interface and can store up to 100 weighted formulas.

■One-click switching between different products.

■Three-level access control.

■ Application

■ Customers

■ Exhibitions

■ Packaging & Delivery

● Our machines undergo comprehensive testing and commissioning before shipment to ensure stable and reliable performance.

● Equipment is packaged in thickened wooden crates with shock and moisture-proof interiors to effectively prevent damage during transportation.

● We partner with several professional international logistics companies and support a variety of shipping methods, including sea, air, and land transport.

● Ensure the equipment arrives safely and on time at your facility.

TAGS