|| Product Introduction

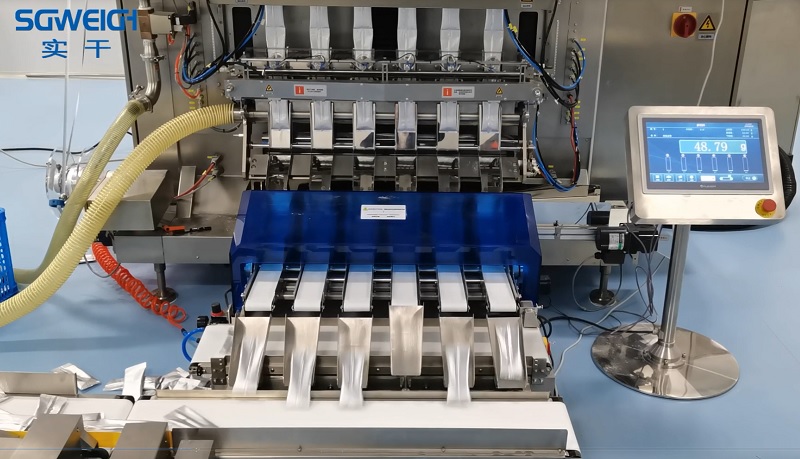

On automated production lines,Six-lane Checkweighers are precision weighing devices designed for high-volume production demands.Small Bags Inline 6 Lane Checkweighers can simultaneously perform real-time weight checks on products from six parallel production lines, ensuring that every product meets specifications and rejecting defective items.

|| Tech Specifications

Model:SG-6X

Weighing Range:1-100g

Accuracy: 0.01 gram (depending on the product)

Sorting Speed:40-60pcs/min (one lane)

Conveying Speed:20-100m/min

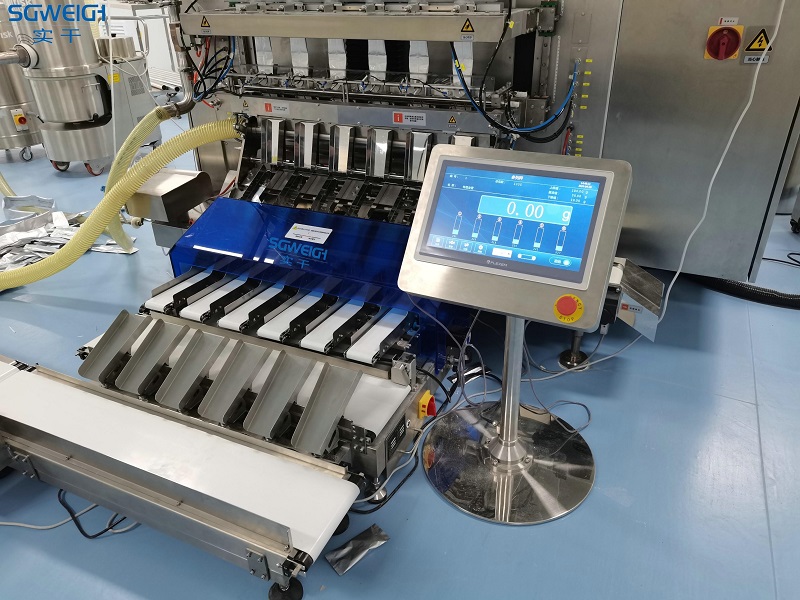

Operation Method:Touch operation

Conveying Direction:Can be placed according to the actual situation on site

Elimination Method:Lifting Rejection

Belt Height From The Ground:450±50mm (can be customized according to customer requirements)

Machine Structure:Stainless steel (SUS304)

Power Supply:220V 50-60HZ

Power:About400W

Windshield:Thick acrylic (to avoid airflow interference)

|| Main Features

1. Multi-column synchronous checkweighing, high efficiency

The 6-column checkweigher can simultaneously check the weight of 6 packaging lanes, significantly increasing production line capacity, especially suitable for high-speed multi-column packaging equipment.

2. Independent weighing & independent rejection

Each column is equipped with an independent weighing unit and rejection system. Abnormal products are only rejected from the corresponding lane, without affecting the continuous operation of other columns.

3. High-Precision Weighing System

Utilizes high-sensitivity weighing sensors to ensure stable and reliable weight detection accuracy even at high speeds.

4. Compatible with Multiple Packaging Formats

Suitable for various product formats such as strip packs, bags, and small packages, meeting the online weighing requirements of different materials and packaging specifications.

5. Compact Structure, Easy Production Line Integration

Modular design, small footprint, can be directly integrated with multiple rows of packaging machines, suitable for production environments with limited space.

6. Intelligent Control and Data Management

Equipped with a touchscreen operating interface, supporting quick parameter switching, weight data statistics, and anomaly recording, facilitating quality management and traceability.

7. Stable Operation, Low Maintenance Costs

Reasonable structure, stable operation, suitable for long-term continuous production, reducing downtime and improving overall production efficiency.

|| Application

Pharmaceutical Industry: Online testing of granulated tablets, suppositories, and small-volume injections.

Food Industry: Coffee sticks, candy, and small packages of condiments.

Daily Chemical Industry: Shampoo trial packs and sample strips.

|| Customers

|| Our Exhibitions

|| Packaging & Delivery

● Our machines undergo comprehensive testing and commissioning before shipment to ensure stable and reliable performance.

● Equipment is packaged in thickened wooden crates with shock and moisture-proof interiors to effectively prevent damage during transportation.

● We partner with several professional international logistics companies and support a variety of shipping methods, including sea, air, and land transport.

● Ensure the equipment arrives safely and on time at your facility.

TAGS