■ Product Introduction

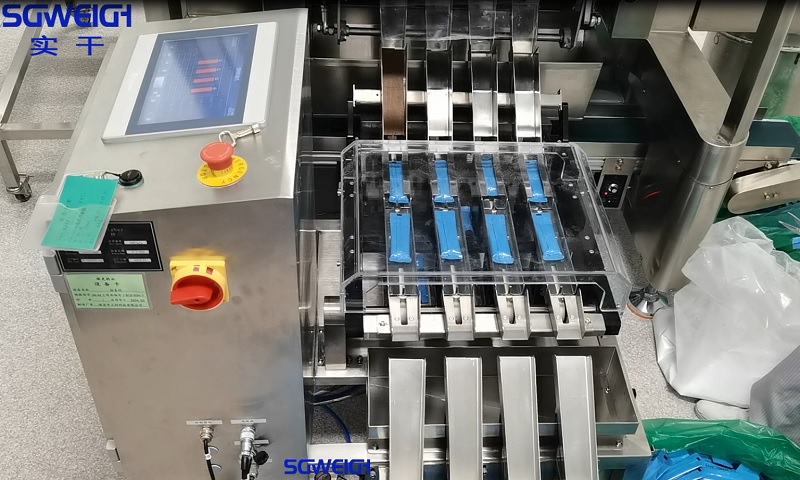

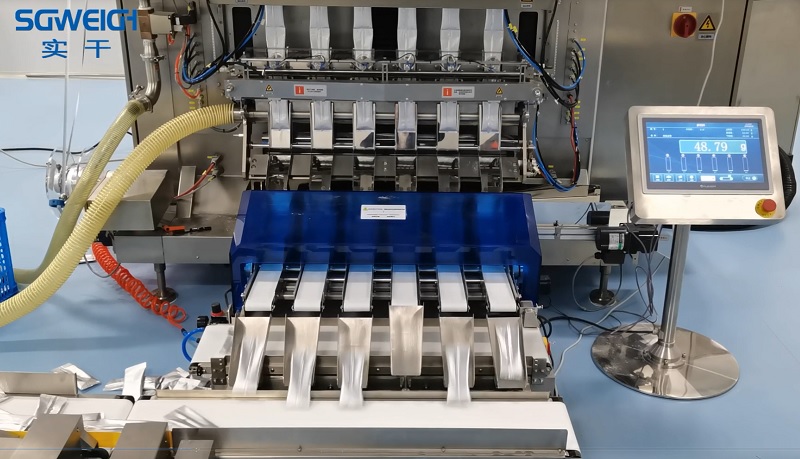

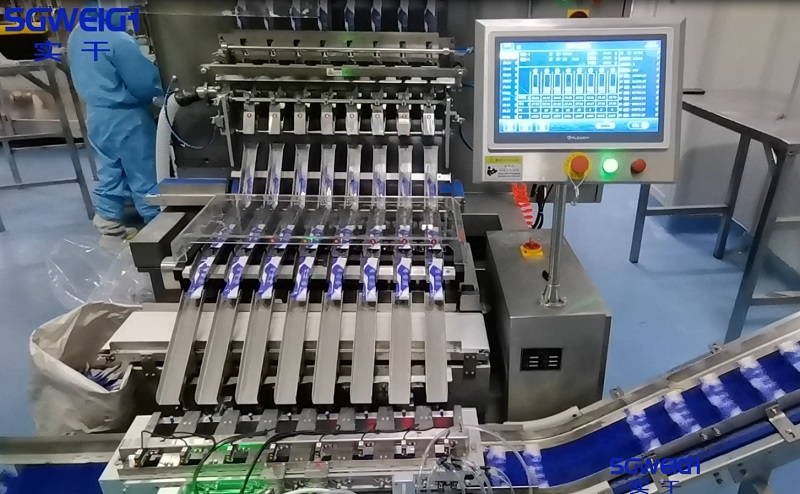

Precise Multi lane Checkweigher is a high-speed, automated industrial system designed to accurately weigh multiple products simultaneously as they travel on a conveyor. Unlike single-lane systems that handle one product at a time, multi-lane systems divide a wide product stream into several parallel lanes (e.g., 2, 4, 6 or more) to dramatically increase throughput while maintaining high precision.

■ Tech Specifications

Model:SG-6X (Customizable)

Weighing range:1-50g

Accuracy:0.01g

Weighing speed:The single-lane speed can reach up to 70 pcs/min (depending on the length of the product)

Restrictions of product:L:180 W:40 H:2-20(mm)

Operation way:Touch screen

Operation screen:12 inch screen

Material:Stainless steel(SUS304)

Power supply:220V 50-60HZ

Power:About 200W

■ Main Features

1. Multi-lane

The checkweigher can handle multiple lanes, enabling the system to process a large number of products simultaneously.

2. High-Speed Weighing

Designed for high-speed operation, it can process thousands of products per hour, making it ideal for fast-paced production environments.

3. Accuracy

Overweight or underweight products can be detected based on preset thresholds.

4. Automatic Sorting

After weighing, products that do not meet specifications (overweight or underweight) are automatically rejected.

5. Integration with Other Systems

It is often integrated with other production and quality control systems, such as metal detectors and multi-line packaging machines.

6. Flexibility

Multi-lane checkweighers can be customized with different conveyor configurations, speeds, and weighing capacities to suit specific applications, product sizes, and industry requirements.

7. User Interface

Equipped with a user-friendly interface and three levels of administrative permissions.

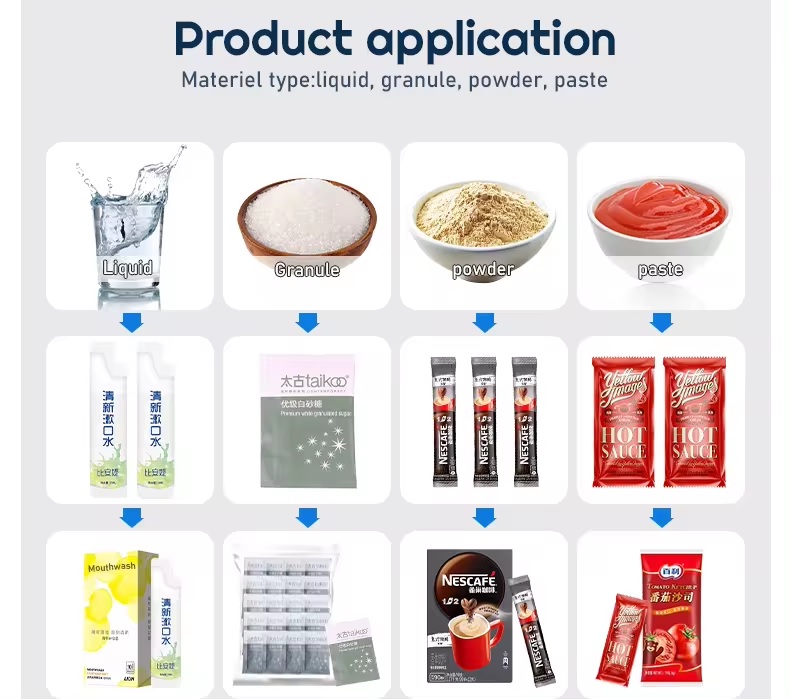

■ Application

■ Customers

■ Exhibitions

■ Package & Shipping

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

TAGS