Product Introduction

The SG-220 Vacuum Bagged Meat Food Checkweigher is used to check whether the weight of a single product matches the set target, and the sorting device automatically rejects substandard products. The new high-integrated modular control system provides comprehensive production quality statistics.

This 0.01g High Precision Check Weighing Scale offers superior stability and accuracy, featuring a self-learning function for easier operation and remote assistance for convenient control. It accommodates various product weights, package formats, and sizes, with both standard and custom designs available to meet operational needs.

SG-220 Food Checkweigher

Tech Specifications

Type:SG-220U

Weighing Range:5-1500g

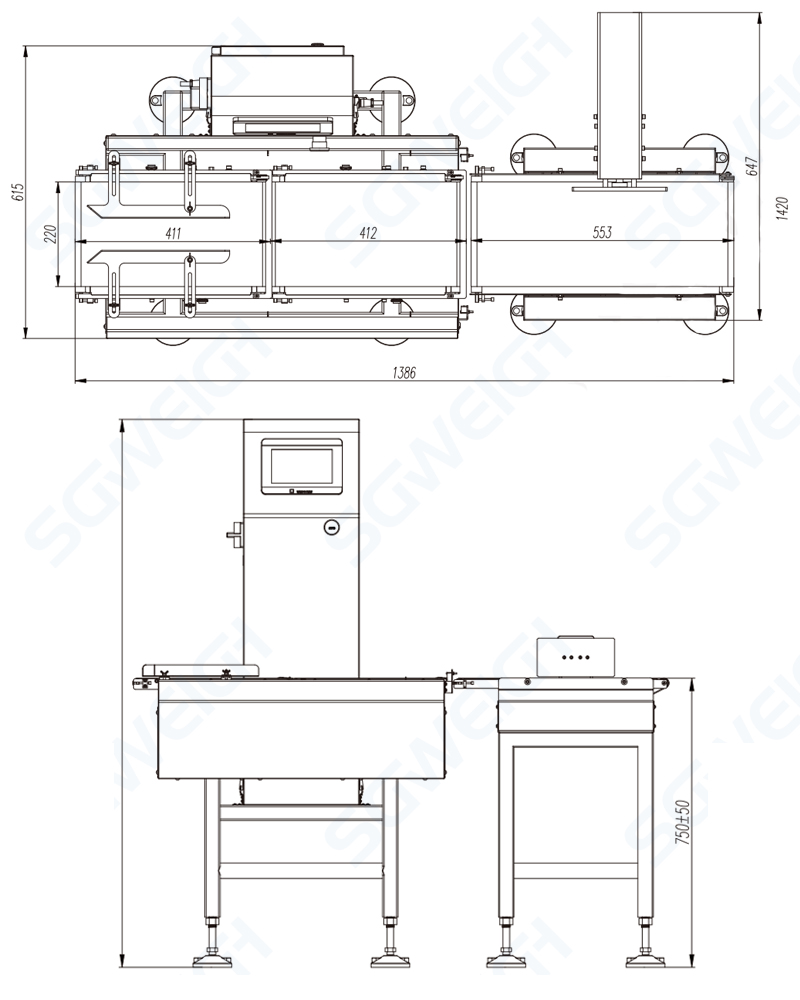

Limited of product:L: 300 W:220 H: 3-200mm

Accuracy:±0.2g Depends on product

Division Scale:0.1g

Belt Speed 0- 60m/min

Max Speed:100 pcs/min

Belt Width:220mm

Machine Weight:65kg

Power Supply:AC 220V 50HZ

Power:200W

Main Material:SUS304 stainless steel

Remark:The properties of the tested products and the use environment are different,and the detection speed and accuracy are also different.The actual test is used as the standard.

Main Features

1. Standard stainless steel conveyor structure, easy to clean and simple to maintain.

2. Three-level operation authority management, support self-set password.

3. 100 product formula preset storage.

4. Touch screen human-machine dialogue.

5. The machine can be customized according to needs.

6. The production data of the checkweigher can be easily exported via USB or Ethernet.

7.Precise Weight Measurements for Product Consistency.

Application

This checkweigher is widely used across industries such as food, pharmaceuticals, agriculture, and cosmetics, providing accurate and dependable results to ensure quality and regulatory compliance.

Our Company

Our Customers

Our Exhibitions

Package & Shipping

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.